Steel Flange

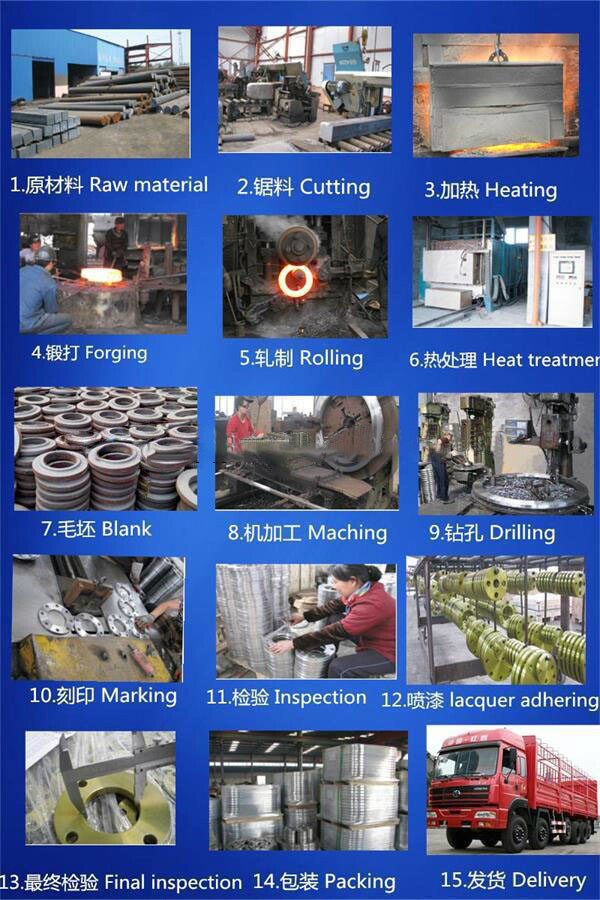

Product Pictures:

Ut sic brevis descriptio:1. Application:

Ut sic brevis descriptio:1. Application:

Nam sigillum vel connect of fistulae / tub-e lines

2. Materialis:

304,304L,316,316L, chalybe carbonis vel alia materia in petitione

3. Latin;

ANSI,DIN,JIS,BS,EN1092-1

4. Size:

DN15 (1/2″) ad DN5000 (200″)

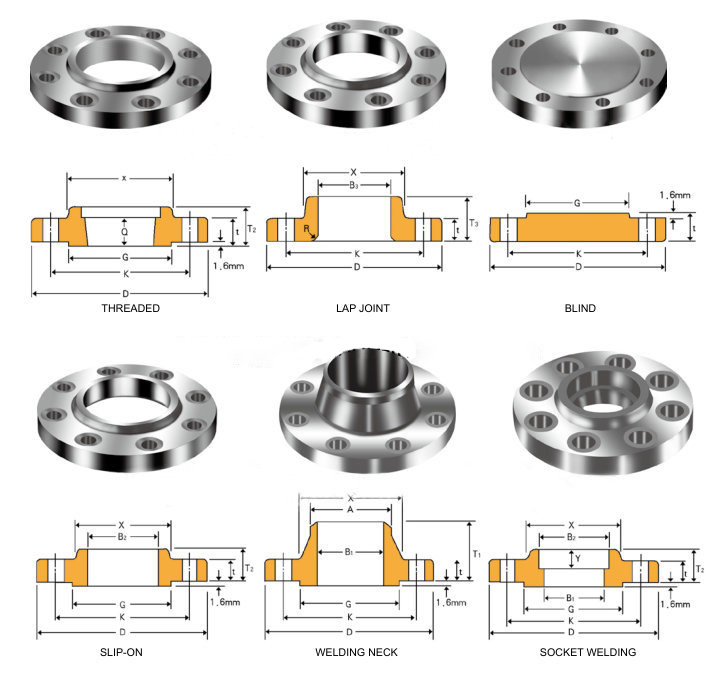

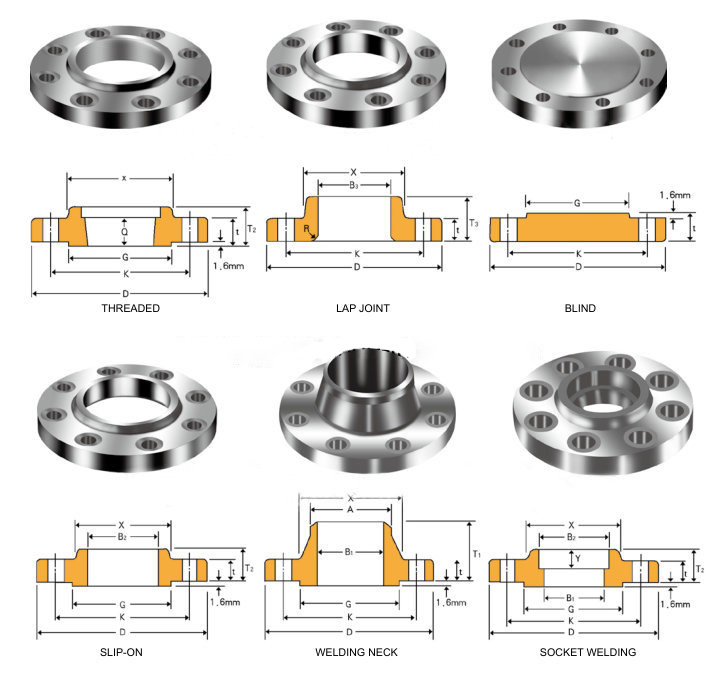

5. Typus:

Post Flanges, nervum Welding Flanges, Caecae Flanges, Aliae Flanges

| Flange Materials | Carbon Steel: ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH | ||||||

| P250GH, P280GHM 16MN, 20MN, 20# | |||||||

| Stainless Steel: ASTM A182, F304/304L, F316/316L | |||||||

| Genera LABIUM | Labi in laminam Flange / Tab LABIUM, labi in Hub LABIUM/Bossed FF/RF/RJ (anulum-iuncturam) | ||||||

| Welding Collum LABIUM/WN LABIUM / solve LABIUM / Lapped LABIUM / Backing LABIUM | |||||||

| Blind Flange/Blank flange, Lap Joint Flange/LJ Flange FF(plana facies) RF (faciem elevatam) | |||||||

| Tabernaculi Weld LABIUM / Magis Flang Threaded LABIUM / Screwed LABIUM | |||||||

| Solve LABIUM/Lapped LABIUM Backing LABIUM RTJ/o-Ringi | |||||||

| Custom Flange/Special Flange Hot/Cold/Electro Gavanized Flange) | |||||||

| Signa | ANSI/ASME/ASA B16.5 FLANGES, ANSI B16.47 A/B FLANGES | ||||||

| JIS B 2220 FLANGES, KS B 1503, DIN SERIES, UNI, EN1092-1, BS4504 | |||||||

| BS 10 TABLE D/E/F FLANGES, SANS 1123 FLANGES/SABS 1123 | |||||||

| GOST12820-80/GOST12821-80, NFE29203/NS/AS/ISO/AWWA FLANGES | |||||||

| Pressura & Ratings | 150LBS, 300,600,900,1500,2500 ANSI, ASA B16.5 | ||||||

| PN6 PN10 PN16 PN25 PN40 PN64-DIN/UNI | |||||||

| PN6 PN10 PN16 PN25 , PN40 PN63-EN1092-1/BS4504 | |||||||

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5,PN4.0-GOST12820-80 | |||||||

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5, PN4.0, PN6.3. -GOST12821-80 | |||||||

| 600kPa, 1000.1600.2500.4000.-SINE 1123 | |||||||

| 5KG, 10KG, 16KG, 20KG, 30KG, 40KG-JIS B2220/KS B1503 | |||||||

| TABLE D, TABLE E, TABLE F-BS 10, AS2129 . | |||||||

| ORDO D, ORDO E, CALSS F, AWWA C207 | |||||||

| Superficiem treatment | Rubigo praeventionis , Black Pain coating or phosphating Treatment with Black Color | ||||||

| Varnish Paint Coating, Oleum Varnish Coating, | |||||||

| Electro Galvanizing Coating (Cold Galvanizing, Colore aureo vel argenteo albo, crassitudine coating 20~30μm) | |||||||

| Calidum intinge Galvanizing Coating (Coating Crassitudo 200μm circa) | |||||||

| Technical | Forging | ||||||

| Applicationem | Aquae opera, industria navi, Petrochemical & Gas industria, Potentia industria, Valvae industria | ||||||

| et generalia incepta tibiis connectens etc. | |||||||

| inspicienda | Quality Control System-Bene Equipments and Machinery-Bell Workers and Engineers | ||||||

| stipare | Lignea cursare vel ligneis causis vel sicut Customers 'Requisita | ||||||

| Pensio conditio | L/C Aut XXX% Promovetur T/T et A statera solvenda Post exemplum B/L | ||||||

| Tempus adferendi | XXX diebus post Promovetur sive L / C * | ||||||

| Post-Sales Service | Ordines et Products Semita System | ||||||

Epistulam tuam hic scribe et mitte nobis